Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Apr 2019

Wind-side and lee-side venting

Is this important?

As a grower and advisor, I am continually learning. The more I discover about precision growing, long term practices are brought into question. Having open discussions with growers, in regards to these new theories, is something I believe is constructive. Over the next few G2G editions I want to look at some of the theories, from a grower’s perspective, and how, if at all, they can be implemented into our growing situations. Your feedback and questions are most welcome.

I have believed, for a very long time, the importance of everything being as even as possible in a greenhouse. Even temperature, even irrigation, even transpiration throughout a crop. A bug bear for me has been greenhouses built with too much slope. Falls have been necessary to efficiently drain the rain away quickly, but never the less it equates to a slope in your greenhouse. This will lead to uneven air temperatures with hot air rising to the higher end and cooler temperatures at the lower end of the greenhouse. The distance and degree of the slope, leads to variation of transpiration rates within different areas of different structures. The cost to production is not hard to visually prove. Greenhouse companies have had little choice and have had to build with falls. However, over the past few years the engineering of greenhouses has improved so much that things like posts are being used as downpipes, so the need for such large falls are being negated.

Wind side venting:

A few moons ago, when I was starting out in my growing career, I was influenced to use lee-side venting over wind side venting for many reasons, which were valid and logical theories at that time. As new technology, and new scientific information, becomes available, I question the practices I implemented. I think this is one of the great things about growing in a controlled environment, how every detail, for potential gain, is looked at by some very smart people. For myself, I need to understand these theories and how to (or not) best apply them to each and every different greenhouse structure I advise to.

As a young grower, I used leeside venting almost by default. It was advised and built into the computer system! It was always a great way to maintain higher humidity levels in a greenhouse when I wanted. I still see the benefits for cucumber crops that are struggling and how a reduced air movement (depending on outside windspeed) can help protect crops. However, in modern tall greenhouses the effects of this are less important, as the top of the plant is a long way from the vents.

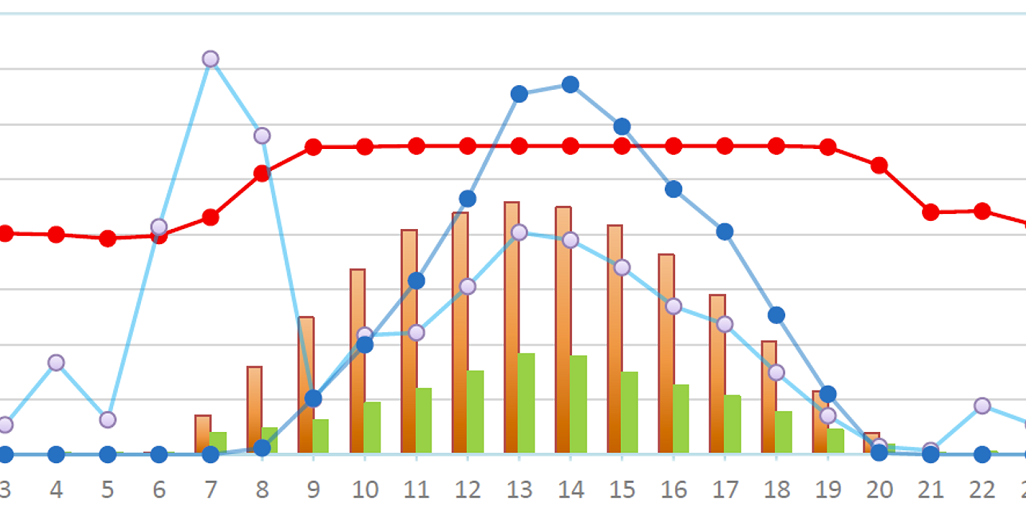

What I did not take into account was the actual air movement, when using leeside vents only, and the effect on moisture distribution within the greenhouse. Thinking back to my greenhouse, it starts to make sense why the west side of the house always had slightly more vegetative plants, it wasn’t necessarily air temperature but too higher moisture or humidity levels. As I understand now, by only using leeside venting air is pulled/sucked mainly into the greenhouse via the vents closer to the east side of the greenhouse. The movement of moisture and heat then (basically) moves horizontally back to the west end of the house before rising and exiting the greenhouse. This definitely had the effect of trapping humidity or moisture but all I was doing was creating an uneven climate and air flow, including an unevenness in natural C02 distribution. In complete contrast if I was using only wind side venting the opposite would have occurred with cold air entering the west side and moisture exiting on the east side of the greenhouse.

It makes relative sense then that if both lee side and wind side vents are opened evenly air movement and moisture exchange will be more even between each bay. It would help ambient C02 being distributed evenly. Now that greenhouses are generally built much higher, than in the past, the gap between the top of the plant and the vent are further apart, therefore the effect from ‘squeezing’ wind-side vents to reduce excessive movement in plants should be less of an issue then for lower structures.

A question I have is ‘At what wind speed should we be using our influences to control the opening of the wind side vent?’ For example if the wind speed is 10ms, it is very warm and to control the environment we need 60% venting capacity, should the wind-side and lee-side both be at 30% open or should the wind-side be at 10% and the leeside 50%? So, what are the parameters or target figures we should be aiming for?

I will be suggesting to growers that they think about using wind side venting to help create better air flow. It does make sense, however, as I demonstrated by my question above I can’t give the perfect formula when I still have many questions that require answers.

In the next G2G edition I will write about the role of fans for air distribution and moisture distribution. Horizontal or Vertical, what are the experts suggesting?

I appreciate your comments. Please feel free to comment below or on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

Article Written by Stefan Vogrincic, Consultant, Grower2Grower

Article Edited by Marie Vogrincic, Editor, Grower2Grower

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Greenhouse Production in the Future – Mike Nichols

(Video of session now available) Excellent online webinar hosted by De Ruiter/Bayer Australia

An observation about Chlorosis effecting Tomato Plants.

Design a Semi Closed Greenhouse with Hortinergy

Direct Air Capture (DAC) is now a reality— Onsite CO2 generation scalable for both large and small operations