Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Nov 2020

What caught my eye

Strawberry season in full swing

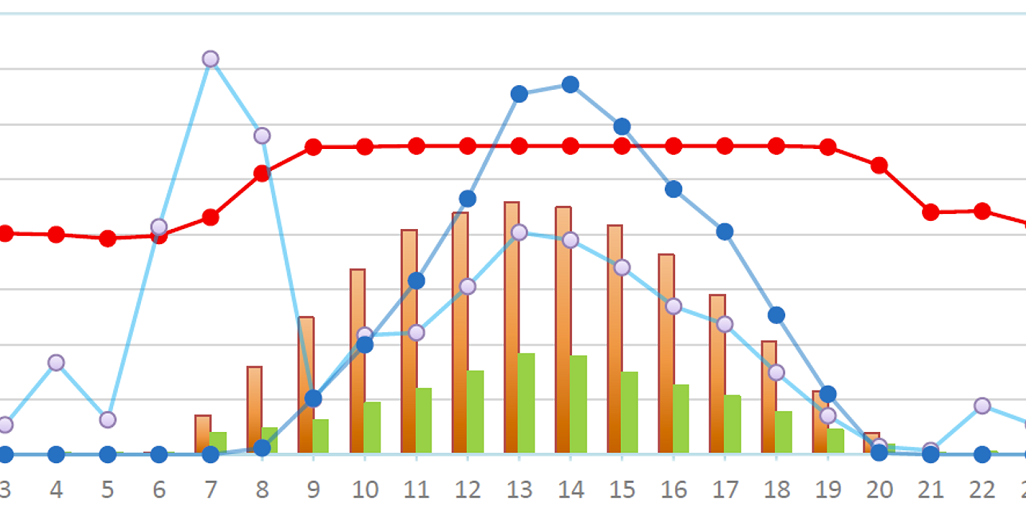

What caught my eye: It was interesting to see the data below published in a recent United Fresh post referring to strawberry production in NZ

New Zealand’s strawberry season is in full swing with the annual harvest from mid-September to April expected to reach its peak in November and December. With hydroponic growing becoming more popular, the season is much longer than in the past.

Strawberry growers are spread from Auckland to Southland, with around 65 percent of the annual crop grown in the Auckland region due to its climate, soil types and proximity to a large labour pool as well as key markets. Approximately 14 million plants are grown each year contributing 8,000 tonnes of strawberries to the market.

The 2019 strawberry season saw industry value reach over $33 million, with around $6 million of that sent to export markets, predominantly those in Asia and the Middle East.

Using the figures above, each individual strawberry plant will approximately produce just over two 250 gram punnets each. This seems more than acceptable but how does this volume compare to that achieved growing in greenhouse tunnels and table tops systems. Basically, low tech to high-tech greenhouse structures would blow traditional outdoor production and labour costs out of the water. With the right varieties it is quite feasible to estimate, even if there was not an increase in the total number of plants grown in New Zealand each year, production which could double or triple per plant with better growing conditions offered by protected cropping. Improved growing systems, high health runners and better producing varieties have already transformed the industry internationally.

By building high-tech growing facilities the growing season could conceivably never end. However, it is likely for several years to come that low-tech greenhouse structures with no energy inputs will be the norm. Currently strawberries imported from Australia during late winter have been very good value for the consumer. Competing with outdoor Queensland winter strawberry production could slow down NZ grown winter strawberries using high-tech, high input structures for now. NZ tomato growers have struggled with imported Australian tomatoes for a very long time, and unless the market in Australia is strong during winter (like this winter) it has continually been a thorn in our side and has continued to dent returns for NZ growers trying to produce tomatoes in the winter for the domestic markets.

Even with unheated low-tech greenhouse structures the volume and quality of strawberry production will skyrocket in a positive direction. Low-tech greenhouse structures offer a very small amount of protection from cold weather conditions. Never the less it will still be enough to see strawberries picked earlier than crop’s planted outside and the quality will surpass anything grown conventionally outdoor in the soil if done correctly. Birds, pests and diseases will also be easier to manage.

Extra Volume:

Current export volumes are valued at $6 million. If the volume of strawberries produced keeps increasing in the next few years then all of these extra strawberries will need a market. Unless New Zealanders rapidly increase their consumption of strawberries then exporting is key. Current international markets need to be expanded and new ones identified. Securing long-term contracts would create certainty and create jobs.

The elephant in the room is that strawberries need to be exported by air. Until this pandemic is under control and our world slowly returns to some degree of normality then exporting into foreign markets, without stating the obvious, is complicated or perhaps non-existent without planes flying. Maybe the government and Air New Zealand could think about the business case for converting some of their parked-up passenger planes to air freight NZ produce that needs to be picked, packed and delivered to the end user within days of harvest.

I appreciate your comments. Please feel free to comment on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

Article Written and compiled by Stefan Vogrincic, Consultant, Grower2Grower

Article Edited by Marie Vogrincic, Editor, Grower2Grower

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Greenhouse Production in the Future – Mike Nichols

Industry spearheads adoption of labour-saving tech with $52M boost (Australia)

a1 Apple Website Launched to Complement Brand Refresh

(Video of session now available) Excellent online webinar hosted by De Ruiter/Bayer Australia

Merry Christmas and Happy New Year 2024