Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Sep 2021

Weather Conditions Affect Quality

Application With a Spray Gun

It is that time of the year when growers should prepare to apply diffused and shading products to their greenhouses. Not all growers have the ability to use an automatic spraying boom or are able to use helicopters for applying coatings on their properties. This post looks at some handy hints for manual application of Redusystems products.

ReduSystems products are easy to apply manually. Manual applications can be done with equipment ranging from a backpack sprayer for smaller areas to professional pump-sets similar to the ones used with machine application. The most important item for a manual application is an adjustable spray gun to ensure even coverage while still being able to reach far enough. The result depends on the weather conditions, the worker’s workmanship and the characteristics of the equipment used. The spray gun set should comprise a diaphragm pump with a minimum pumping capacity of 40 l/min, sufficient hose length and an adjustable spray gun to reach all parts of the greenhouse.

UNIFORM DISTRIBUTION

If the application is done the correct way, the coating will flow into a homogenous layer. The challenge is to evenly distribute the product on the greenhouse cover. This requires a balance between the speed of walking, the dilution of the spraying solution and the setting of the spray gun. Careless application can cause the coating to sag. This causes the coating to be too thin at the top and too thick at the bottom near the gutter. The layer is not as wear-resistant at thin spots and this reduces the intended effect on the crop. When an operator has insufficient experience working with a spray gun it may be better to apply one or two extra buckets to compensate for any sagging.

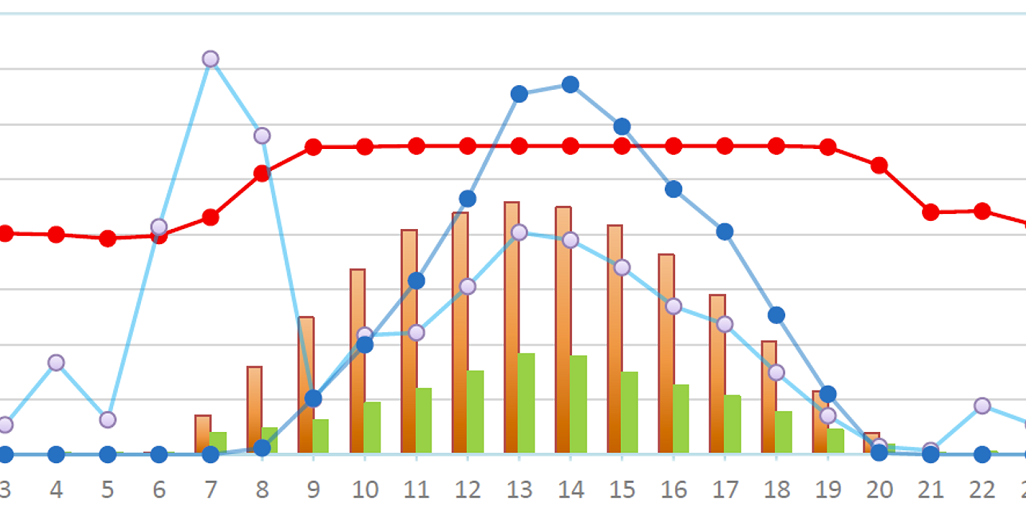

WEATHER CONDITIONS AFFECT QUALITY

- Apply the coating to a clean and dry greenhouse cover to obtain the best wear resistance. Pay special attention in case of new plastic. The oil layer must be removed, otherwise the coating will not adhere properly.

- Apply the coating during dry weather with relative humidity < 80% on a dry greenhouse. A wet greenhouse cover dilutes the layer. When the drying time is too long this may cause excessive run-off and therefore an uneven coating.

- Keep an eye on the weather forecast. Do not apply during precipitation or when precipitation is forecast over the short-term (within 12 hours). Rain damages a coating that has not yet totally dried.

- Apply at a temperature between 10 and 25 degrees Celsius (5 and 25 degrees Celsius for ReduSol and ReduClean). Otherwise the drying time will be too long and the coating will be wet during the night and may become damaged due to condensation.

- Do not apply when windy (max. 7 km/hour). The layer may become too thin and overspray may occur.

.jpg)

APPLYING THE COATING

- Calculate the total required quantity of water and coating. Approx 1,700-2,000 litres of spraying solution per hectare is required (total of water + ReduSystems product).

- Fill a mixing tank of sufficient capacity with clean water.

- Pour the selected number of buckets of ReduSystems product into the mixing tank with water.

- Mix the spraying solution with sufficient force to create a homogeneous solution. Check that there is no remaining concentrate at the bottom.

- Apply the solution evenly on the greenhouse cover.

- Only spray when weather conditions are right.

REMOVING A COATING

- Determine the quantity of water and cleaning product and follow the same preparation instructions used for mixing the coating.

- Verify that the drains and the surroundings are suitable for the flow-through of rinsing water. Prevent ingress if possible.

- Apply the solution evenly on a dry greenhouse cover and let sit for at least 15 minutes before rinsing with water. A strong rain shower within one week will also wash off the coating.

- Ensure that the coating is entirely moistened. The coating on missed sections will not be removed.

- To avoid temporary white discolouration do not discharge rinsing water to stagnant waters; install the drainage system below the water surface; and discharge the rinsing water to a large moving bodies of water with sufficient capacity, where allowed

- If you discharge ReduSystems products into the reservoir, check the water’s usability afterwards, particularly the pH.

DOSING

ReduSystems products control the light entering the greenhouse. This benefits production and quality. The desired effect is highly dependent on the thickness of the coating layer. In other words, on the number of buckets product per hectare. We determine the optimal thickness on the basis of studies and we are constantly learning from actual practice. This means that our recommendation to use a specific number of buckets per hectare is well founded. The use of more or less buckets (or loss of product due to improper application) has adverse effects. Using fewer buckets than recommended reduces the intended effect on your crops. A shading product consequently might shade too little radiation or heat. Furthermore, low concentrations reduce the layer’s wear-resistance. A shading product consequently might shade too little radiation or heat. Furthermore, low concentrations reduce the layer’s wear-resistance. When too many buckets are used the effect is reversed; in this case, you could lose too much growlight and thus compromise production or quality.

For every crop and situation in the world, the ReduWizard app on our website provides recommendations about the ideal product and the right quantities to be used.

https://www.redusystems.com/en/articles/applying-coatings-yourself-produces-maximum-results

SAFETY

-

Be sure to use fall protection when walking on the greenhouse cover.

-

If ReduSystems products come into contact with the skin or eyes, rinse off with water.

-

If ingested, contact a doctor.

Contact your local Horticentre branch for RedySystems products

.jpg)

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Greenhouse Production in the Future – Mike Nichols

(Video of session now available) Excellent online webinar hosted by De Ruiter/Bayer Australia

An observation about Chlorosis effecting Tomato Plants.

Design a Semi Closed Greenhouse with Hortinergy

Direct Air Capture (DAC) is now a reality— Onsite CO2 generation scalable for both large and small operations