Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Aug 2020

Tom Moerenhout – Senior Consultant

Grower2Grower SME Eggplants

I am pleased to announce Tom Moerenhout accepted to join the Grower2Grower Subject Matter Experts group. Tom is a highly experienced eggplant grower and was running his own greenhouse company in the Netherlands till end of 2018. After he sold his company, he got frequently asked for advice because of his 35 years of growing experience. Today he is consulting growers with daily operations such as climate control, crop maintenance, nutrition and other cultivation topics. He is specialized in eggplants (aubergines) and has also been growing tomato and cucumbers.

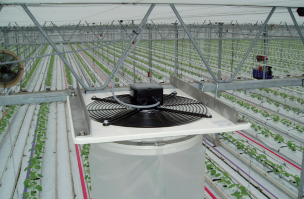

Tom started growing in a greenhouse that was 1.6 ha, when taking over from his dad in the 80’s. When Tom sold his company, the greenhouse had expanded to a growing area of 2.5 ha with expansion possibilities of 2.5 ha. The property was serviced by a co-gen boiler system, used supplementary CO2. Eggplants were grown in stone wool substrates on gutters. Tom grew with an energy screen, used vertifan’s for more uniformity in temperature and airflow within the crop. In 2012 a lighting trial of Signify was installed, which we will come back to later.

Picture used used in research report by WUR about vertifan’s at Tom's property. Tom was one of first growers to install it (many followed later)

Tom's old greenhouse being planted with a new crop (several years ago)

I asked Tom to give us some insights to growing and his experience:

How and when did you become interested in growing Eggplants

Since 1990 I was growing 3 cucumber crops per year. In autumn 1991 we were infected by Cucumber Green Mottle Mosaic Virus (CGMMV) the first time. Therefore, we had to grow a different autumn crop in 1992 so we could eradicate the virus. This was a non-grafted eggplant crop which got us interested. After some years of consideration, we decided to convert over to eggplants in 1995. Other trigger points were that crop change was only once per year and it was not necessary to harvest on Saturdays. This allowed extra time to spend with my young children in the weekend as well.

How have the ‘physical’ growing techniques changed and evolved since you began growing 37 years ago. Eg plant density and labour techniques (pruning and fruit loading, fruit size).

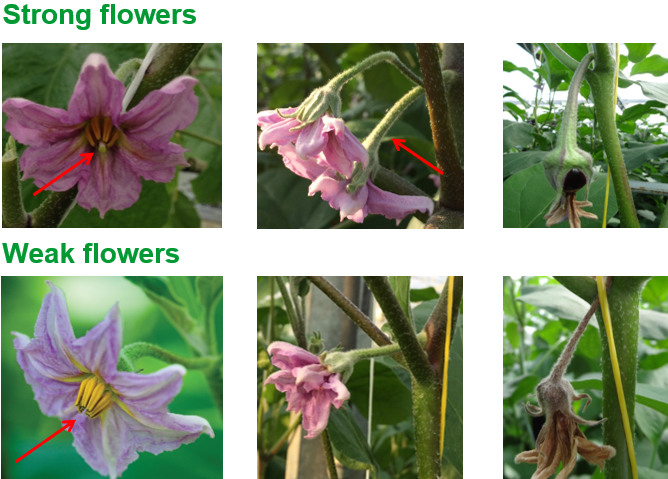

Grafting was a huge improvement for eggplants as the plant has a naturally weak root system which could not stand a high plant load. Grafting is done by using a tomato rootstock and eggplant scion. Main benefits were the increased yield and quality. Top yields in the Netherlands increased from 45 kg/m2 in 2000 to 65 kg/m2 nowadays. Average fruit weight before grafting was 285-300 g and nowadays 300-350 g is more common. Grafting resulted in less root diseases (Pythium and Fusarium) and less Mucor (wilting of flowers caused by Rhizopus fungi). With grafting the crop system also changed from in general 2-3 stems/plant towards 3-4 stems/plant. I grew 3 stems/plant with density of 5 stems/m2. An added bonus with grafting, the thorns on the calyx disappeared so there was then less fruit damage as well.

Looking to harvesting the eggplant crop is one of the most difficult crops to learn as a crop worker. Usually it takes almost 6 months to combine speed & efficiency. As you keep side shoots with fruits (1 to max 2) next to the fruits from the main stems (the same as capsicums). Recognizing side fruits is crucial they have thin fruit stems and turn earlier to red (over ripening) So you need to harvest them in time, often only 175 gram fruits. This might not be beneficial in all countries when the market is demanding larger fruit size, for example New Zealand.

Left fruit from main flower, right is side shoot flower. Observe the thin fruit stem and how it gets red too quickly so should be harvested early approximately 150 grams.

Left is dull fruit, weak peel and if you press too hard, fingerprint will be visible, during post harvest life this is potential rotting spot / right – fruit is shiny high quality fruit.

Has climate management changed and if it has what are the benefits from an energy saving and growth perspective have you been able to achieve?

Since early 90’s energy screens installed to save energy but recent years show that we can do much more with screens to optimize climate inside the greenhouse. First, I installed a Cogen heating system in 1996 in addition to the gas boiler. Higher 24 temperatures were possible to increase production with the development in varieties. Last years trend is to grow with the light so accept higher temperatures when you have higher light levels.

As substrates have evolved and new varieties have come to the market did this alter your irrigation strategies, if yes how did this alter the way in which you would control your Water content, EC, PH etc?

Started growing in soil as my dad did previously but we changed already to stone wool in 1982. In the early years the water holding capacity was not that great so dry slabs at the top. With the new generation slabs I changed quickly to 10 cm high GT Master slabs with about 11 L/m2. Aubergine plants will develop a massive root system so to be able to steer with irrigation a higher volume is required. One of the things we did well is that we never had a real issue with crazy roots. Combination of a generative growing strategy, building a natural eco system in your slabs (for example use of compost tea) and use of Trichoderma was working for me. Other top growers in the Netherlands adopted this generative growing strategy to prevent crazy root problems. Something I am proud of.

Do you see supplementary lighting playing an important role for increasing winter production.

As one of the first growers to test artificial LED lights in aubergines since 2012 we can say that it is really difficult. As again confirmed by recent research in the Netherlands (https://www.kasalsenergiebron.nl/nieuws/meerdere-factoren-vragen-aandacht-in-aubergineteelt-met-led-belichting/). We had one row with inter lights, later increased to two strings of internight but we never had the confidence to increase this area. It looks like it is difficult for the crop to convert the extra photosynthesis into higher production. Changing the light spectrum might be a solution but let’s see what the future brings.

What are the top five areas of advice that are critically important for successfully growing quality and high yielding crops of eggplants?

-

Plant load (#fruits/m2)

-

Harvest frequency

-

Average fruit weight during the season

-

Pollination (humble bumblebees and honeybees)

-

Vital root system (starts during propagation)

Below is just some of Tom’s advisory services. These could include different options to suit the requirement of each customer:

- Climate Control advice

- Irrigation and substrate advice

- Fertiliser recipes

- Climate computer monitoring

- Integrated Pest Management (bio control

- Answer questions via WhatsApp within 24 hours’

- Plant Density requirements

- Plant pruning

- Labour Techniques

- Harvest planning & prognosis

- Service backed up by Grower2Grower

Grower2Grower will provide a service that is used only if requested.My extensive knowledge will provide a backup for all international SME and give the grower local support.

If you are interested in enquiring about the services of Tom Moerenhout please contact stefan@grower2grower.co.nz for more details including terms and conditions.

.jpg)

Above Tom in the packhouse and below an overhead photo of his past property.

(1).jpg)

I appreciate your comments. Please feel free to comment on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

Article Written and compiled by Stefan Vogrincic, Consultant, Grower2Grower

Article Edited by Marie Vogrincic, Editor, Grower2Grower

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Wally van de Westerlo nearing retirement

Sales training & coaching – Helping teams improve conversions & build better customer relationships

Céline De Neve Joins Agro Solutions Team in APAC Region

Michael Bednarz new Powerplants Australia CEO

Te Mata Exports Announces Retirement of Founding Director Murray Tait