Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Jul 2019

Taste’n See, 1680 Tonnes of Strawberries

PCA Northern Farm Tours

Last week, on the final day of the PCA (Protected Cropping Australia) conference, delegates were given the opportunity to complete farm visits around the surrounding area of Brisbane. All three of the farm visits, on the Northern tour, I attended were magnificent and definitely worth the time to go and experience. The hospitality and information shared was nothing less than superb.

The final destination of the day was not a greenhouse but an open field, growing strawberries in Bellmere, Queensland, of which most was now on table/gutter systems. All the substrate used was coco fibre and all supplied with pressure compensated drip irrigation. Priva systems were also used as part of the operation. The delegates were treated to some real insights from Grower Managers Dave Fairweather and Laura Wells.

Producing 1680 tonnes of strawberries per annum is quite an astonishing accomplishment for the joint owners of the business the Schiffke and Stothart families. Laura Wells is daughter of business co-founders Merv and Marilyn Schiffke. You can read a previous article written about the farm and the owners on the link below. The farm operations began over 45 years ago.

Since the previous article, written in 2017, the farm has even more table/gutter production with approximately 22 ha now erected. The huge advantage of being out of the soil is the saving in back breaking labour picking costs, much better control over the irrigation and management of the plants. There is still issues with not growing in an open greenhouse (Cravo type) structure such as the heavy rain, causing damage, and the disease pressure this causes, especially powdery mildew which can cause the fruit to split. The ROI on a retractable covered structure is still too hard to justify but Laura said they will continue to investigate that option in the future.

It truly was a pleasure to visit the farm and listen to Laura’s explanation of how the farm is operated, she certainly has her finger on the pulse. I was very impressed with her knowledge and expertise. Laura’s father taught her that if you are “really a farmer you’re on your farm” and she lives by this philosophy and is very hands on with the two farms operations.

Below in the photo gallery are observations and further facts about this farm:

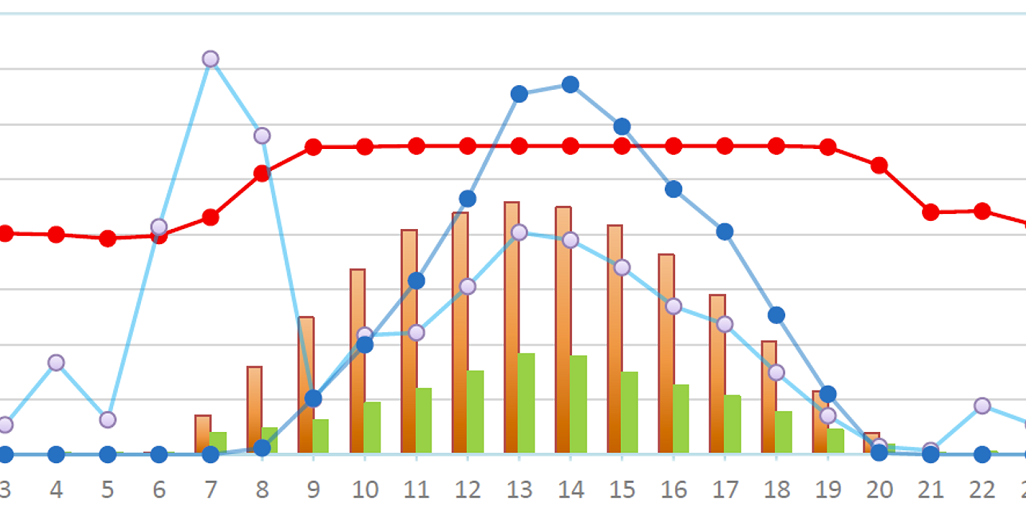

The irrigation is run off a computer system similar to a greenhouse. Light accumulation is collected from this weather station.

Water is supplied via a huge damn on the property and according to Dave even in the most extreme drought, they have experienced, they still never ran out of water.

This particular property had 12 valve stations with 3 separate feeding lines. The drippers were 2 litre/hour compensating drippers. There was ample capacity to irrigate all the plants with their requirements on the hottest times of the year. The EC, PH and WC are monitored daily with staff randomly checking bags around the farm each day. There were also fixed sensors for EC and PH.

The water quality is very good, both Dave and Laura have seen a decreased usage of water growing in the table systems.

Huge amounts of coco fibre are used on this farm (great to be a coco supplier!) and currently the coco is being reintroduced into the soil parts of the property. Going forward a new form of re-using the used media will be addressed.

Young, high-health plants are received in plugs from a local nursery and from soilless grown systems now. Runners are not collected and stored for the next season for plant health reasons. The main varieties grown are Festival and Fortuna, (Californian cultivars) with a trial of a Queensland bred variety called Red Rhapsody. All cultivars are day neutral. Planting is done once a year

Insects such as Two spotted mites are controlled using IPM. Fruit fly does appear to be harder to control on the table, gutter systems. Bird’s, that damage fruit, are unbelievably controlled by Ducks!!! Still not quite sure how that works but go Ducks.

Growing on tables has increased 1st grade %. A huge positive.

Planting and picking have become so pleasant, now the table systems have been introduced, that older long-term workers, who only liked working in the packhouse, have now wanted to go back into the field. In turn this has meant a huge reduction in staff turnover. Training new staff is seen as a large cost, so the ROI on this alone needs to be calculated. And how do you calculate for happy staff?

An external strawberry consultant is used, even though both Laura and Dave are generally in front of the advice they receive they still believe that to be very important to always have that outside independent opinion to make sure nothing is missed.

The runoff from the bags is left to drain on to the ground. The entire farm is mowed and manicured beautifully. This has actually preserved job,s as the efficiency of the table systems has decreased the labour hours needed growing on the ground. However, automation of mowing the land is being looked at. The grass grown is seen to be using any excess fertiliser to prevent it leeching into the soil. The view at sunset was breath-taking. Nathan Hewson MD Hydroponic Solutionz NZ (middle) also attended the farm tours and enjoyed the experience.

I appreciate your comments. Please feel free to comment below or on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

Article Written by Stefan Vogrincic, Consultant, Grower2Grower

Article Edited by Marie Vogrincic, Editor, Grower2Grower

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Greenhouse Production in the Future – Mike Nichols

Industry spearheads adoption of labour-saving tech with $52M boost (Australia)

a1 Apple Website Launched to Complement Brand Refresh

(Video of session now available) Excellent online webinar hosted by De Ruiter/Bayer Australia

Merry Christmas and Happy New Year 2024