Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Nov 2023

Tailored approach to irrigation for MJ crops

“Grodan’s solutions play a part in giving us a bigger and faster yield of high-quality flowers than we could achieve with soil,”

Swiss medicinal crops producer Grow Motion has been operational for less than a year, but already has ambitious plans for future expansion. Grow Motion is currently growing CBD (low THC content), therefor it is not necessary to obtain an official license in Switzerland. “Grodan’s solutions play a part in giving us a bigger and faster yield of high-quality flowers than we could achieve with soil,” says Benjamin Gutsch, who oversees the production facility. “And when we decide to scale up, we know that Grodan’s uniform growing media will give us perfect results every time.”

After three years of planning, construction and arranging licences, medicinal crops producer Grow Motion – based in Solothurn, Switzerland – recently became operational. “We are now seven months into production, and we’re happy to already be cultivating 6,400 plants,” says Benjamin Gutsch, head grower at Grow Motion.

Having previously worked with medicinal crops in Spain and Germany, Gutsch moved to Switzerland in August 2022 to put his experience to good use at Grow Motion’s new facility. He was personally involved in the final preparations, and today he and his team of six people take care of the day-to-day operations at the facility. That currently comprises a mother room and a growing room, each measuring 145m2. “Quality is very important to us, especially because we are selling to the pharmaceutical industry. And Switzerland is a good country in which to make good quality,” he comments.

Clean and time-saving solution

“When I became involved in this project, I said we should definitely work with Grodan. I’d been working with NFT systems for many years, including with Grodan blocks, and I’d always been very happy with their performance,” comments Gutsch. “Besides being known for product quality, Grodan also offers good support, so we saw it as the best fit for us as a company. And the excellent service we’ve received so far confirms that we made the right decision.”

“As an inert medium, Grodan’s stone wool enables us to work much more cleanly than with coco peat, for example, so that we can comply with the strict standards and SOPs required for medicinal crops. Additionally, unlike soil, stone wool doesn’t contaminate the drippers in the irrigation system and make them harder to clean, so it saves us time,” he continues.

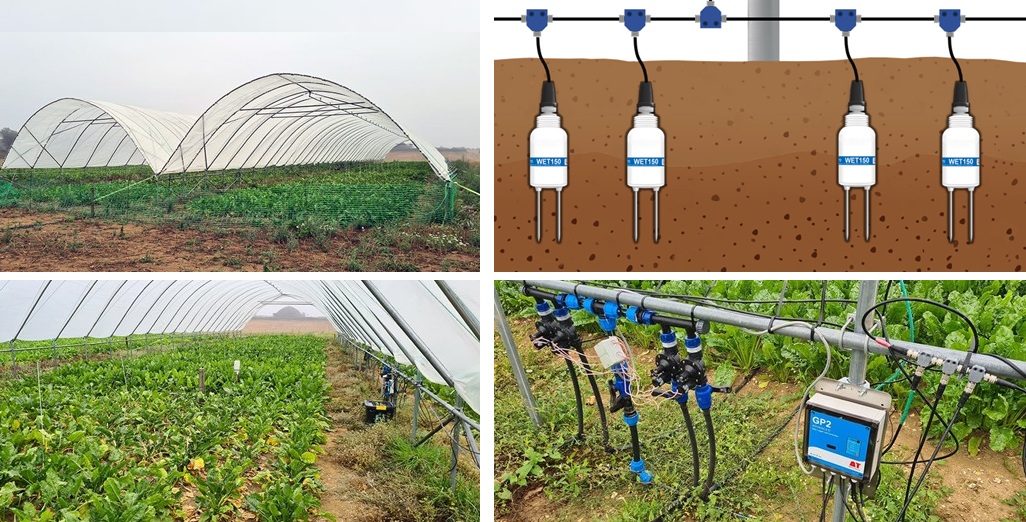

Tailored approach to irrigation

Grow Motion sources all its growing media from Grodan, specifically two different sizes of plugs and one size of blocks. “We use the bigger plugs for our mother plants and the smaller plugs for the clones, which we subsequently place directly on top of the blocks,” says Gutsch. “We were keen to use blocks rather than slabs, partly because blocks are more visually appealing when visitors come and look inside our facility through our showroom window,” he explains. “But blocks make it harder to get a uniform water content when using a dripper, like we do. So the Grodan experts helped us to set up the irrigation cycles at the beginning and developed an adapted plan for us.”

Overcoming challenges

To maximize the production surface, Grow Motion has a three-layer setup in the growing room. “However, this presents its own challenges. For example, the microclimate this creates inside the room can be pretty difficult to manage, posing a greater risk of fungus. The Grodan blocks help us to minimize that risk,” he comments.

“Additionally, to ensure the plants don’t grow too close to the lamps and block the radiation, we need them to stay wide and bushy rather than tall. To achieve this, we work with a very short vegetative phase followed by 60 days of flowering in the cultivation phase,” says the head grower. “Based on Grodan’s advice, we soak the blocks completely based on weight and then let them dry back for 8 to 10 days. This approach is working really well for us now, and even allows us to use a slightly higher EC.”

Steering the crop with more precision

Gutsch monitors the crop closely using Grodan’s sensors and the GroSens interface, and he is clearly a big fan. “The sensors are amazing and I would advise everyone to use them if they’re working with blocks because it makes a grower’s life so much easier. And the system connects easily to our Priva computer, so all the information from both the climate computer and the sensors is at our fingertips in GroSens for analysis,” he comments.

Bigger and faster yield

“I know from experience that stone wool supports more oxygen in the rootzone and a faster uptake of nutrients. Therefore, in combination with the sensors and GroSens, Grodan’s solutions really play a part in giving us a bigger and faster yield than we could achieve with soil,” he says. “And that’s very important for our project in terms of keeping our customers and also our investors happy!”

Each plant currently produces 65g of flowers, according to Gutsch, which is a very good yield for such a short vegetative phase, especially since the facility is still only in its first year of operation. But he is a firm believer in continuous improvement and has set his sights high for the coming years. “I enjoy looking for ways to make the yield even bigger, better and faster based on minimal inputs. With some small adaptations, based on my own insights and advice from the Grodan experts where necessary, I soon hope to achieve 100g per plant,” he claims.

Uniformity supports scaling up

“This is a huge facility and we have plenty of space to add more growing rooms – up to 14 in total, with at least a double layer in each. But we don’t want to scale up until we – and the markets – are ready,” he states. “Until then, we will continue to refine our cultivation approach and build our sales markets. And since Grodan’s growing media support uniformity and repeatability, we know that when we do decide to scale up, we will get perfect results every time,” concludes Gutsch.

To contact to learn more about your local distributor contact:

Daan Berkers

Senior account manager New Crops MJ International

M +31 6 2733 4675

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

The Rise of Plant-Driven Irrigation

The BBRO Tackles Drought Risk in Sugar Beet Production

Botrytis Alert: Key Strategies to Minimize Losses

(Best of 2024) Fleecegrow turning wool into substrates a reality

Less fertilisation and higher yields with Ambiorix iron polyphosphate