Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Jun 2021

Humidity influences (Technical)

Tricky

The shortest day has arrived and the day length will now slowly begin to increase – but there is still the worst two months of winter ahead. There is almost a false sense of security that light hours will increase and therefore it is time to start working crops harder. It is quite the opposite. From experience we are in for some very low light levels and inclement weather. Fruit loading and temperatures should be maintained at levels that don’t weaken greenhouse crops and allow plants to maintain manageable winter production. Some growers may take extra shoots in early July in anticipation for the spring but with that comes a warning to manage and be flexible to reduce fruit load if required. It is an especially tricky time for capsicum growers setting their first fruits. If the weather is slightly better than average you could set and hold an extra fruit per plant on the first set but following that If the weather is unkind, this could potentially cause some abortion on the second set.

Humidity Influences:

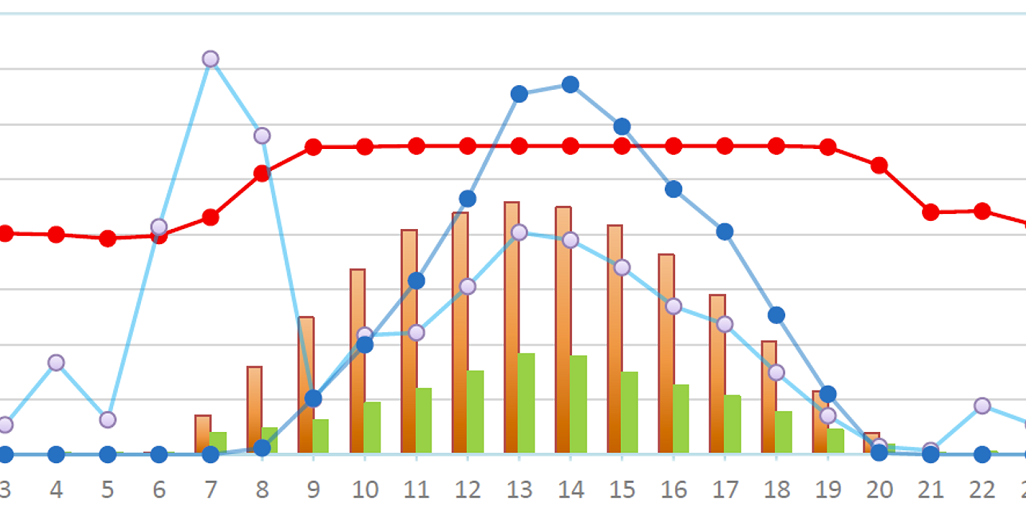

High humidity and fungus issues are a problem and should be managed carefully over the next five months. The temptation with the very high energy prices will be to minimise pipe or air heating. The other tools in your arsenal will be irrigation and your computers humidity influences. If you have to be energy conscious, I would be very careful how you irrigate your plants – be very much on the generative side and really manipulate the balance of your plants – if you make them to vegetative by kindness you will then potentially have more fungal pressure to deal with which would require more heating tools or spraying. This is in part due to the increase in leaf area index and the transpiration of a bigger leaf hence more water/humidity to control. We want leaf panels to collect the small amount of light available but you don’t want a soft vegetative plant = big leaf surfaces (generally).

If you are prepared to grow with a higher humidity before your settings kick in you should definitely grow a more generative plant. If you have venting influences on humidity, then be mindful you may be bringing cold air into your greenhouse so there is a balance to be struck. There is still a decision to be made when it comes to pre-warming the greenhouse in the morning. If this was the only time a customer said I could use energy then I would not be scrimping in the morning – it is a must in my book but you need to be careful to restrict the heat and vent scenario.

If this was your only choice, what would you rather have 12-degree greenhouse temp with 90% Relative humidity (RH) or 15 degrees with 95% RH? You could argue that the amount of water vapour per m2 is similar. I would prefer more temperature but be happy to sacrifice a small amount of temperature in the morning period to prevent a fruit sweat. I would try to maintain an active environment and use my venting/humidity influences with tight P bands tied to outside temps. If you don’t control the early part of the day – then you will have no option but to irrigate later which is the reaction to a non-active environment.

On a side note, if your glass has condensation on the inside (which it will for longer periods of the morning especially) and you do little to control your humidity then this film of condensation could prevent up to 8% of light transmission until it is dried up and gone – consider the rule of thumb that 1 % of light lost is 1% of production lost. By keeping your vents closed, using minimal heat you could cause other detrimental outcomes for your crop.

The temptation for the tomato crop above could be to use your screen and keep the vent down – this will keep temperature in but humidity will be higher. Still use your screen but be willing to vent a very small amount to help with reducing the amount of moisture in your greenhouse – use the Absolute Humidity settings/influences if you have them available on your computer systems.

(Below explanation on Vent P Bands)

Optimization of Proportional Plus Derivative Band Parameters Used in Greenhouse Ventilation by Response Surface Methodology:

Ventilation is one of the most important factors in greenhouse cultivation because the inside temperature of greenhouses rises rapidly in warm climates, and this high temperature may be detrimental to plant growth. The ventilation system in multi-span greenhouses is often controlled by a proportional algorithm. The relationship between temperature changes in the greenhouse and ventilation is not linear. Conventional ventilation strategies mostly employ a proportional band (P-band) control, which contains various settings related to solar radiation, outside temperature, and wind velocity. In practice, these settings may have a relationship with the set ventilation temperature. However, it is difficult to find optimized settings because they must be changed according to the greenhouse location, shape, and local climate changes.

Source https://www.hst-j.org/articles/xml/ZzWo/

Cover photo – young capsicum crop during low light period. Balancing the fruit load with available light is very important to avoid abortion.

Article written and compiled by Stefan Vogrincic

All Article’s checked and edited by Marie Vogrincic

I appreciate your comments. Please feel free to comment on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Greenhouse Production in the Future – Mike Nichols

(Video of session now available) Excellent online webinar hosted by De Ruiter/Bayer Australia

An observation about Chlorosis effecting Tomato Plants.

Design a Semi Closed Greenhouse with Hortinergy

Direct Air Capture (DAC) is now a reality— Onsite CO2 generation scalable for both large and small operations