Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Jan 2020

Heating and Venting is Ineffective and Wasteful

Greenhouse Growers are Increasing Vegetable Yields by Controlling Humidity

Article provided by Brinkman Australia

Growing vegetables in a greenhouse has lots of advantages. Protecting your plants from nature’s elements lets them grow faster and larger. But, as every grower knows, it can also become a hotbed for diseases, which are often caused by high humidity.

Traditionally, growers combine heating and ventilation to reduce humidity. But many growers have been making the move to dehumidifiers, which provide much better control and help save energy.

Greenhouse Humidity Problems

Humidity is one of the biggest issues in greenhouses. Plants transpire more than 90% of the water they take in, constantly pushing humidity upwards, 24/7.

Without releasing humid air from the greenhouse, it can quickly reach saturation – the dew point. At this point water starts to condense on different surfaces, including leaves and fruit. This is when most humidity related diseases develop and spread.

In tomato crops, for example, humidity leads to diseases such as powdery mildew, Alternaria, late blight, Septoria leaf spot, tomato pith necrosis and various other mildews.

High humidity, even without condensation, hurts the plants’ ability to transport nutrients, slowing down growth and inhibiting development.

These problems aren’t just true for fruits and vegetables, of course. Humidity impacts all crops – herbs, flowers, medical cannabis etc.

Heating and Venting is Ineffective and Wasteful

As mentioned, the traditional way to deal with greenhouse humidity is by combining heating and ventilation.

Hotter air can hold more water vapor, so heating effectively reduces the relative humidity. But it doesn’t actually remove any water vapor, so once temperatures drop, humidity will spike.

To deal with this, growers ventilate, releasing the humid air from the greenhouse. This method can be effective under the right circumstances, but it’s also extremely wasteful.

Growers invest a lot of energy into heating the greenhouse. Some of which is aimed towards controlling humidity, but mostly it’s done to provide the right temperature for the plants. Releasing humid air means losing this heat. So, growers must continuously heat the greenhouse, just to avoid condensation. Needless to say, this is a waste of resources and money.

However, the bigger problem with heating and venting is that it often isn’t a viable solution to humidity. For example, during the night, when it’s cold outside, ventilation won’t reduce humidity, only introduce cold air to the greenhouse. Venting also won’t help when it’s raining or humid outside, as is common in many regions and seasons in New Zealand.

Controlling Greenhouse Humidity with Dehumidifiers

The only way to control greenhouse humidity around the clock is by using a dehumidifier. Physically removing water vapor from the air ensures low humidity, even when temperatures drop during the night.

Treating humidity from the inside lets growers keep the greenhouse closed, retaining heat, and maintaining optimal temperatures. This makes it extremely efficient in terms of energy. Even though it may sound counterintuitive, using a dehumidifier reduces energy use, saving as much as 50% on heating and energy costs.

Keeping the greenhouse closed increases overall control over the climate, leading to higher quality and larger yields, as well.

NZ and AU Growers are Using DryGair for Humidity Control

Many NZ growers are making the move to dehumidification.

Southern Belle Orchard in Matamata, for example, have been using DryGair dehumidifiers to keep their pepper greenhouses dry, increasing yields by 15% due to the improved climate. But owner, Frans de Jong says the extra production is just a bonus. The decision to incorporate dehumidifiers was made for the energy efficiency – “Energy saving is one of the most important factors to keep growing in hothouses viable”.

Since using dehumidification, de Jong reports that his heater usage has gone down, and he’s been using much less energy overall. He’s also happy to add that humidity diseases are no longer an issue for him – “Fungal and bacterial issues are nonexistent, as we have full control over the humidity. This also cuts costs as no sprays are required to deal with any problems.”

Matthew Dent, of Royal Brinkman Australia, understands the difficulty of climate control, “You can’t cheat when it comes to climate, as mother nature always catches you out!”, he declares.

When asked about DryGair dehumidifiers, which Brinkman represents, Dent had this to say: “At Royal Brinkman we take a lot of pride in knowing we deliver real world solutions for our customers. I have total confidence recommending DryGair because it does what it says it does and there are no surprises. We see the benefits it delivers to growers in all crops, on a daily basis, and naturally stand by it 100%.”

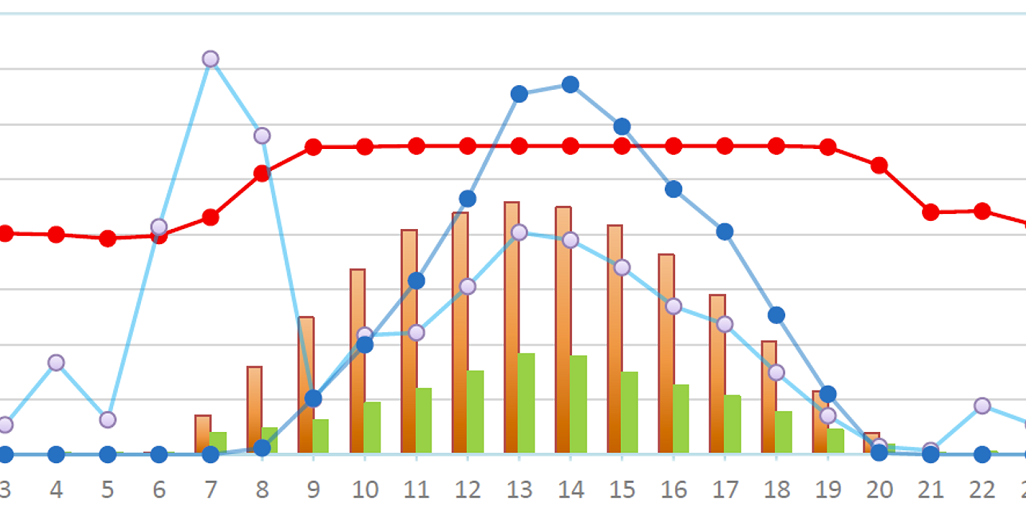

To provide tangible information on dehumidifier usage, DryGair has put together a case study, measuring the impact of dehumidification in vegetable greenhouses. The study was conducted in various tomato and pepper greenhouses and presents the differences between dehumidified greenhouses and those relying on traditional heating and venting.

.jpg)

Contact Mathew Dent for more information

Matthew Dent | Sales Brinkman Australia

18-20 Jarrah Drive, Braeside, Vic 3195

M. 0447-734654 | T. 03 9587 2566

E. matthew@royalbrinkman.com.au

W. www.royalbrinkman.com/australia

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Greenhouse Production in the Future – Mike Nichols

Industry spearheads adoption of labour-saving tech with $52M boost (Australia)

a1 Apple Website Launched to Complement Brand Refresh

(Video of session now available) Excellent online webinar hosted by De Ruiter/Bayer Australia

Merry Christmas and Happy New Year 2024