Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Dec 2020

Growers Mitigate Labour Pressures with BumperCrop’s Efficiency System

Big Impact to Bottom Line Performance

Labour represents roughly one third of greenhouse growers ongoing costs, meaning that even a modest improvement can result in a big impact to bottom line performance. With rising labor costs and Covid-19 related labour pressures, it is more important than ever to run a highly efficient business that optimises staff productivity.

Smart Insights – Data that Makes the Difference

BumperCrop’s high-tech labour management focuses on the labour efficiency elements most important for individual operations with its powerful capabilities that allow for customisation, adaption to existing processes and integration with existing systems. By honing in on the key metrics that matter to individual operations, efficiency can be maximised. Some growers have reported labour efficiency gains of up to 20% and saving many hours of admin time per week.

“In addition to providing more efficiency, we wanted to provide a system that delivers a better outcome overall. Most labor management systems have big upfront costs that result in vendor lock-in, poor support and costly upgrade fees down the road. Instead, we offer an affordable subscription model so growers get value at all times, not just when they start out with the system,” said Managing Director Adam Forbes.

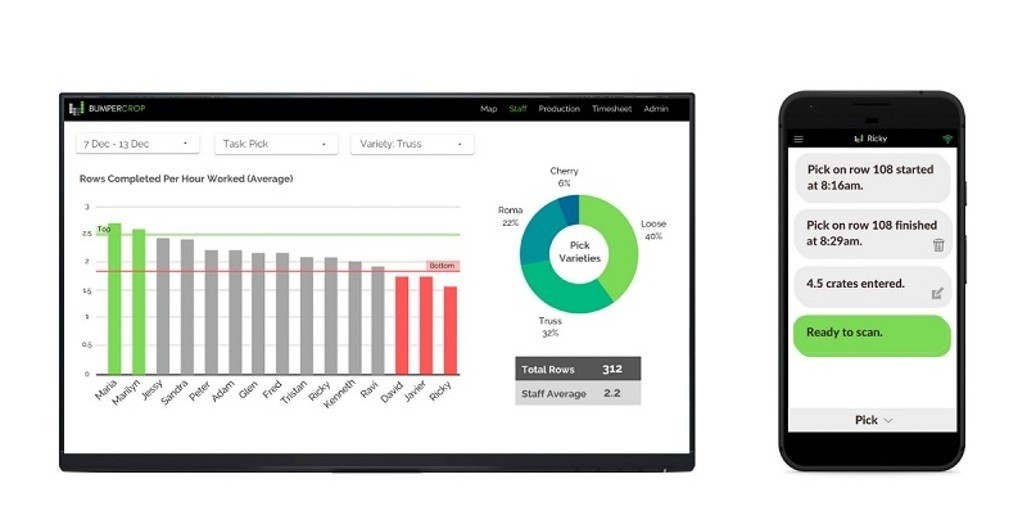

Left: BumperCrop Operational Dashboard, Right: BumperCrop Labour App

Fast to Deploy – Scales as You Need

Growers are busy and don’t have time for extensive meetings or to learn and configure complicated new systems. A trial of BumperCrop’s Labour Management System can be up and running in less than 20 minutes once hardware arrives. After this, it can easily be scaled up as required. This benefits both smaller growers with less staff and large growers who often prefer to start out with a part of their operation.

Improves Performance with Technology

A carefully thought out and thoroughly tested design minimizes the time it takes to input data. WorkWave™ tags allow staff to easily and accurately log work by waving a device over a tag at the end of each row and to input data. Growers view the results in near real time and staff become more motivated, as they are able see their performance on dashboards. Growers are then able to use this data to pay staff based on performance.

Less Time Spent Managing

Growers realise substantial operational savings by spending less time managing and following up with staff. With all tasks and time worked logged in the system, growers can see an overview of the operation and individual staff performances for any time period.

Plan More Effectively

Managers use picking data to more accurately anticipate yields before packing starts, helping to achieve better prices. They can also see an overview of problems identified by staff as they work, or understand how much was picked at the same time last season and which rows yielded the most.

A System that Keeps on Improving

BumperCrop’s team of technology and user experience experts has been working closely with greenhouse growers to perfect their system over the past 2 years. The entire system is cloud-based, which means that improvements, once tested and verified, automatically roll out to subscribers. A growing number of greenhouse operators are using the BumperCrop system as it becomes a trusted partner for small and large growers alike.

.jpg)

Left: Gourmet Mokai Ltd., a 11.4 hectare tomato site that uses BumperCrop’s system.

For more information:

BumperCrop

Adam Forbes

adam@mybumpercrop.com

https://mybumpercrop.com/labour-management-software/

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Octiva acquires Berkvens Greenhouse Mobility

Participate in a short 12-minute online survey focused on fertilizer use and receive $25 Prezzee Card

AP4 Porometer by Delta-T Devices

Direct Air Capture (DAC) is now a reality— Onsite CO2 generation scalable for both large and small operations

Tomato grower applies Tobre after contamination