Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Jul 2023

Groscale, Sandu & Chouhan: “Cover your upgrade costs with a single crop cycle”.

Groscale, Sandu & Chouhan: “Cover your upgrade costs with a single crop cycle”.

Navigating your irrigation system to discover the perfect balance of nutrients, fertiliser and water can seem like an arduous task. In an environment where timing can make all the difference, precision becomes a key factor for taking production to the next level, and automation can be hugely beneficial for maintaining control while eliminating human error. But with the numerous remedies available to growers, knowing where to start can present a whole host of new challenges.

With almost 20 years’ experience growing Lebanese cucumbers, Australian producer Sandhu & Chouhan is familiar with the trial-and-error process of improving greenhouse irrigation systems. Starting in low-tech greenhouses, the company now grows over 32,000 plants and estimates an output of 7-10kg of marketable fruit per plant – a threefold increase in fruit output per plant compared to when they started in 2005.

Co-founder, Karmjit Sandhu, accredits much of this to the company’s continued focus on measuring and improving its fertiliser, water, and chemical use.

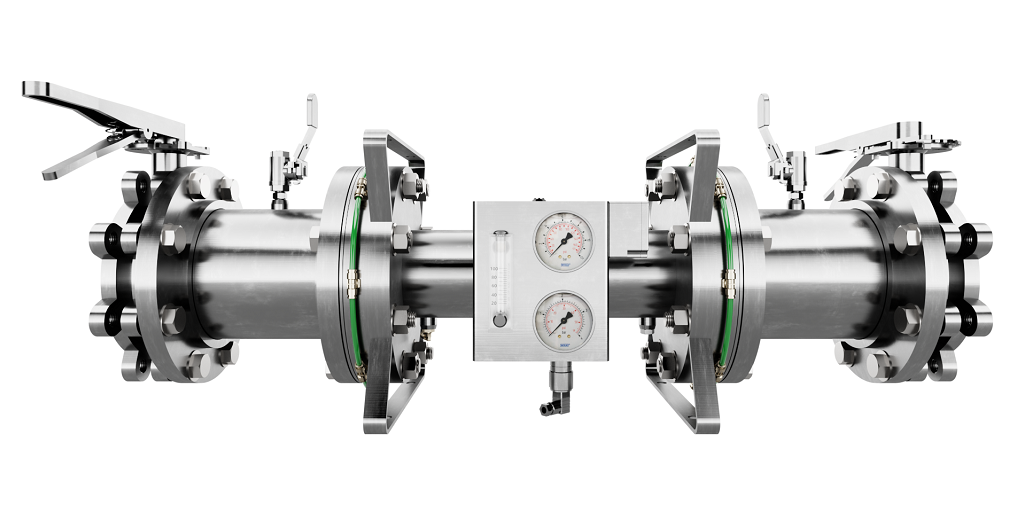

“When we started, our initial Venturi system (A&B tank) irrigated based on time, which created a lot of problems with unmarketable, misshapen produce, incorrect EC/Ph dosing, and high plant mortality,” Sandhu says. “We tried countless solutions – chemical sprays, water treatments, UV filters, media filters, an IPM program – but we eventually had to target the root of the problem.”

“In 2014 we turned to Powerplants and Priva. An irrigation system with a sun radiation sensor allowed us to start feeding the correct EC/Ph and decrease water and fertiliser use. It helped improve our yield and overall plant health but required daily monitoring to set the radiation sensor and check the drip and drain.”

“2022 was when we implemented the Priva GroScale system. While this technology wasn’t available when we started with Priva, the main reason we decided to move to this system were rising fertiliser costs, with some fertilisers increasing price by 300%.”

These latest upgrades have allowed Sandhu and Chouhan to take their automation to the next level, while also giving them better insight into their growing processes and crop health.

“Now that we have wireless weight measurement feedback, the system tells us where the saturation point is and when we achieve drain for the day,” Sandhu says. “We can instruct the irrigation system not to exceed the saturated weight, only irrigating if the plants really need it which results in minimal run-off. The GroScale has also allowed us to accomplish better dry back in the afternoon and evening. Cucumbers are sensitive to having wet roots overnight, so reducing this has significantly increased the health of our plants.”

Since implementing the weight and runoff monitoring features of the GroScale system, Sandhu and Chouhan have seen a 65% increase in marketable fruit and have reduced fertiliser application by 50%. As an added benefit, plant mortality has also dropped 80%, and the healthier crops have also meant weekly spraying has changed to every 2-months.

By keeping an eye on developing technology, Sandhu & Chouhan have continued to make incremental investments in systems that decrease input costs while improving plant health and yield. The process has allowed the company to demonstrate consistent improvements, while also helping them stay up to date on the latest industry knowledge.

For more information, please contact:

Alastair McLean, Commercial Director

Powerplants Australia

E: alastair.mclean@powerplants.com.au

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

(Best of 2024) Fleecegrow turning wool into substrates a reality

Less fertilisation and higher yields with Ambiorix iron polyphosphate

Bluelab Introduces OnePen™

Free Webinar on Controlling Waterborne Pathogens in Greenhouses

Whitepaper elaborates on safe recirculation of irrigation water