Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Sep 2021

Future-Proof Lettuce Cultivation

A Shift Towards Hydroponics

Published on 20/07/2021

Cultivators is continuously conducting research and monitoring developments in the industry. In the past weeks we as a group students of Wageningen University conducted research on the supply chain change of lettuce under supervision of Cultivators. For this research we interviewed stakeholders in the lettuce industry such as growers, builders of hydroponic lettuce systems, financial institutes, and retailers and processors. Below you will find a summary of our findings in our report.

Currently the Netherlands is the second largest agricultural exporter in the world by value. However, the suitable amount of space for expansion in the Netherlands is limited, making it a priority for the Dutch agriculture sector to stay on top of the game. Multiple crops such as tomato, cucumber and pepper have already made the shift from soil-grown to hydroponic production, with lettuce expected to be the next crop to follow.

Technological advancements

Several hydroponic systems have been developed, and so far, two have shown to be currently economically feasible on an industrial scale; Nutrient film technique (NFT) & deep flow technique (DFT). What we see is that based on the desired crop variety, location, and initial investments, growers can choose the most fitting cultivation system and level of automation. As a result of the continuous development in this relatively young industry, no two hydroponic systems seem to be the same. However, we do expect that as technologies are improved and knowledge increases, systems will in turn become more standardized and eventually cheaper.

Below a schematic representation of the two systems is given (figure 1 & figure 2), multiple variations exist using these technologies. For example, we have identified vertical farming systems, NFT fully automated systems, high density deep flow systems as well as NFT moving gutter systems or static NFT systems. Each of these systems is suitable for production of a specific crop varying from baby, teen leaf to small and large heads.

Figure 1. Schematic representation of a NFT system; [P] water pump, [N] nutrient solution (Geilfus, 2019).

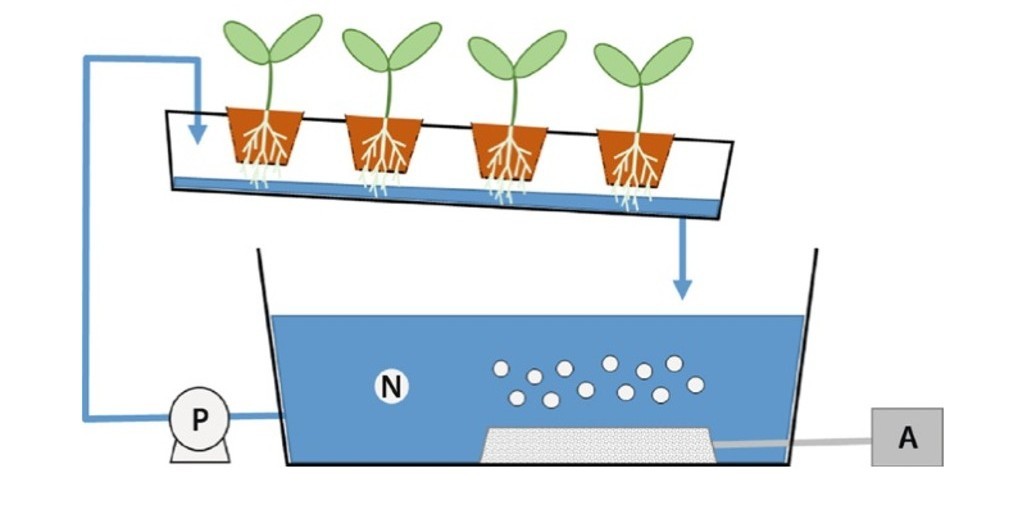

Figure 2. schematic representation of a deep flow system; [N] nutrient solution, [A] air pump (Geilfus, 2019).

NFT consists of gullies, which can be spaced automatically to make optimal use of irradiation at every plant stage. An optimal nutrient mix flows constantly through gullies, past the roots of plants. The constant flow of new nutrients allows for optimal growing conditions. Using multiple gullies allow for differentiation of the nutrient mix adapted on the growing stage of the crop.

DFT is a simple yet robust approach to a hydroponic system to grow crops. A DFT-system consists of a pool with floaters. These floaters contain the plants which have their roots in the pool filled with the nutrient mix. Differentiation of nutrient mixes is less interesting as new and old plants share the same pool. Because the fixed plant density on the floats, the growing area is less efficiently used in case of lettuce heads or teenleaf production.

Vertical farming is not a system on its own, but rather an implementation of other hydroponic systems like NFT, stacked vertically. It has the advantage of being very space efficient, but it cannot utilize the sun for lighting. Because of this, a vertical farm always needs artificial lighting, which drives up the energy demand. As of now, we think that this energy cost makes it unviable compared to regular hydroponic implementations. However, for the early stages of plant growth it is considered interesting, as there is a higher plant density, and the high level of environmental control leads to more uniform crops.

The production of baby and teen leaf is mainly to produce pre-packed lettuce and mixes of salad. It can be harvested and packed on site of the grower potentially changing the current supply chain. Harvesting of full lettuce heads, cleaning and cutting and packing at a processing company might no longer be needed.

The future will tell what the supply chain of lettuce will look like, but it is evident that changes will take place for the benefit of high quality of local produced food.

.jpg)

Future expectations

It is the consensus that hydroponic cultivation of lettuce will increase in the future as there is a demand for year-round delivery of locally produced product by retail. At this stage large part of the production in retail is still produced in soil often in the South of Europe. It is unlikely new open soil growers will enter the market of lettuce. However, conventional production is not likely to disappear completely since popular varieties as Iceberg and romaine lettuce can difficulty be grown hydroponically due to their crop morphology. In addition, hydroponic lettuce needs to compete on price with conventionally produced lettuce from Spain and Italy.

Next to this we see that the new crop varieties and highly automated production systems might impact the supply chain of lettuce. In the new supply chain production will not only be local to market, but also packaging and processing might take place on site of the grower. Products will not only be hydroponically local grown but packed and processed as close to the customer as possible. This will be seen on retail shelves of the future.

Although growing lettuce using hydroponic system brings major sustainability benefits such as reduced water requirements, reduced pesticide usage and less food miles. This type of growing is not deemed biologic and/ organic since it does not follow the current prerequisite set by the EU. Guidelines state that “organic” growing must occur in open soil and this is not the case for hydroponics. A separate quality mark such as “hydroponically cultivated” is unlikely to be successful, but it is possible to use the “On the way to PlanetProof” quality mark to indicate sustainability.

Conclusion

We believe hydroponic systems will keep developing and the supply chain will adapt to new possibilities that come with this innovation. We also believe many more crops will follow the shift to hydroponic cultivation. Less workers will be needed in the future for crop cultivation, but the workers that are needed require more education. System support and human capital are possible limiting factors for the large-scale adoption of hydronic cultivation.

Not only does there need to be an interest from growers and investors, but we also need a new generation that is excited about this wonderful development.

ACT Team: Anthony Vermue, Bart Jansen, Cas van de Voort, Daan van Munnen, Elbert Niemeijer, Harold Weekamp and Lorenzo Nielen

Note by Cultivators:

Cultivators continuously conducts and supports research and development in the industry. In this case we are partner of Wageningen University ACT project program supporting students in the development of their consultancy and research skills. The article is the result of the research and reflects the insights of the consultancy team.

Reference:

Geilfus, C. M. (2019). Hydroponic Systems in Horticulture. In Controlled Environment Horticulture (pp. 35-40). Springer, Cham.

Article supplied by CULTIVATORS

Website: https://www.cultivators.nl/

https://www.cultivators.nl/future-proof-lettuce-cultivation-a-shift-towards-hydroponics/

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Direct Air Capture (DAC) is now a reality— Onsite CO2 generation scalable for both large and small operations

Tomato grower applies Tobre after contamination

KWS inaugurates new R&D facility in Uberlândia, Brazil

Powerplants and RTF Climate Announce Strategic Partnership for the APAC Region