Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Nov 2019

Ecomix Presentation by owner Martin Vadakekuttu

Choosing coco grow bags for hydroponic growing

The third Grower2Grower Breakfast of the year was held at the BNZ partners building in Pukekohe last month. Presentations from Martin Vadakekuttu, Owner of Ecomix, and Peter Butler from the BNZ were both extremely informative.

Martin’s talk offered several interesting facts, demonstrating the huge improvements that have been made recently and highlighted the benefits of the coir his company supplies. Ecomix started a coco manufacturing plant in India in early 2010 with a clean state of the art facility.

THE PRODUCT:

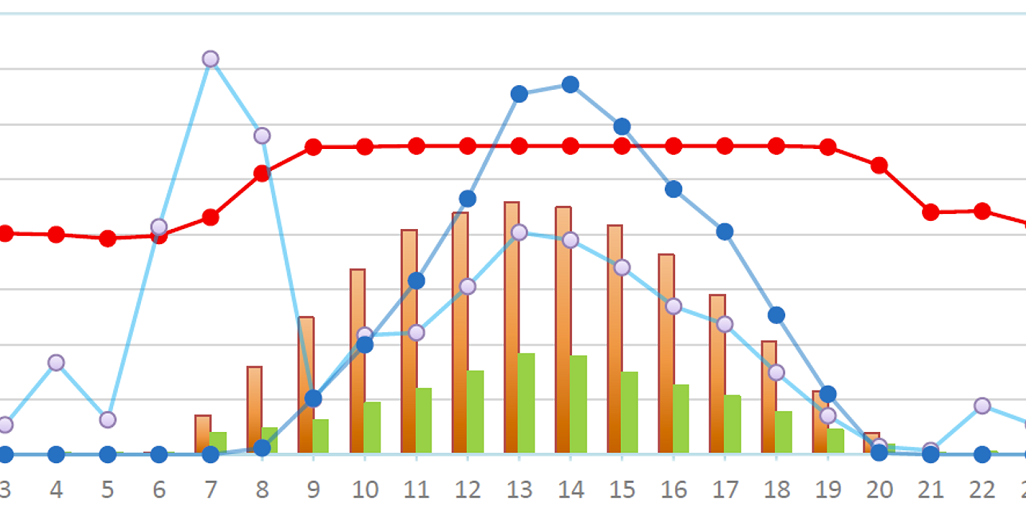

Grow bags are comprised of different particles of coco husk. The particles size distribution defines the grow bag’s texture. The texture of a grow bag is determined by the way in which the particles are arranged while manufacturing.

In Hydroponics, grow bars have a significant short- and long-term effect on the crop performance. There are many important properties to be considered when choosing a grow bag

- Optimum water holding (50-55%)

- Optimum air-filled porosity (20-25%)

- Better drainage

WATER HOLDING CAPACITY:

Water Holding Capacity – the volume of water retained by a saturated growbag after it is allowed to drain. A Kilo of pressed coco slab can expand up to 10 Litres and it will hold water between 5 to 5.5 litres depending on the mixture.

AIR FILLED POROSITY:

Air-filled porosity is the void in the growing media at any point of time, which is not filled with water. Air-filled porosity varies with the sizes of coco particle. Most commonly in grow bags we keep 20% AFP to 25% AFP. It can be altered by adding different coco mixes, husk chips and microchips.

DRAINAGE:

Drainage has an important role in grow bags. Keeping the drain holes at the lowest point of the bag is always recommended. To maintain a better drainage, the micro fine particles in the grow bag mix are to be removed and add different ratios of husk chips .This will improve the AFP in the grow bag and helps a better drainage. If the drainage is blocked for some reason, naturally the EC will be built up at the bottom of the bag and root zone.

Martin covered the common problems found with growbags which were:

1. EXPANSION ISSUES. (SLOW OR NO EXPANSION)

2. UNEVEN HEIGHTS

3. NON-UNIFORM MIX RATIO

4. TOO WET

5. TOO DRY

6. HIGHER EC & TANNIN

7. NO DRIPPER HOLES

8. COMPACTION AT THE BOTTOM OF THE BAGS

SOLUTIONS:

Ecomix developed high quality precision grow bags with unique structure and specific blends. Structural stability throughout the life span of the product is determined by specific blends, special washing and curing. There is no further flushing required to lower the EC and tannin’s, this saves the grower’s time, money, water and nutrients.

Ecomix understands growing is not an easy task. Martin believes growbags are the foundation of the growing “we make sure every step to manufacture the grow bags is the best. At Ecomix everything is possible, we reach out to the growers and understand their specific requirements. With the experience in logistics and distribution we only commit to providing orders which can be delivered on time”. Martin also revealed his thoughts on buffering and not buffering coir. This will be covered in a future article in more detail, but in short the Ecomix product is not buffered but is washed.

Ecomix have a broad range of products for all traditional vegetable greenhouse hydroponics cultivars and also supply product for the berry market, flowers and others.

Selection of Growbags and Slabs:

- Depends on irrigation strategies & crop requirements, growers make the decision to choose the growbag volume.

- Most common bags volumes are 7.5 to 30 Litres.

- Standard coco peat volumes required for plants such as tomatoes, cucumbers, capsicums & eggplants are 3.5 to 4 litres / plant, which is equal to 18 to 24 litres.

- For strawberries, 2 to 2.5L /plant 18 – 20 L volume is ideal.

- Raspberries, 8 to 10 Litres are ideal.

- Blueberries & Blackberries 28 to 30 litres are ideal

Pukekohe cucumber grower Sunny Mahey (left) shows Martin how the Ecomix coir bags are going.

If you are interested to find out more please contact Martin, e-mail: prodoz@bigpond.com or click on this link to go directly to the Ecomix website.

MARTIN VADAKEKUTTU(M Eng.)

(DIRECTOR)

PRODOZ INTERNATIONAL PTY LTD.

(ECOMIX COCO AUSTRALIA/NZ)

Thanks to Martin and the BNZ for allowing Grower2Grower to organise and host this event. If you are interested in showcasing your products to greenhouse growers please contact me for further information.

A most successful morning, thanks again to the BNZ and Whisk Cafe for the breakfast.

I appreciate your comments. Please feel free to comment on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

Article Written by Stefan Vogrincic, Consultant, Grower2Grower

Article Edited by Marie Vogrincic, Editor, Grower2Grower

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Greenhouse Production in the Future – Mike Nichols

Industry spearheads adoption of labour-saving tech with $52M boost (Australia)

a1 Apple Website Launched to Complement Brand Refresh

(Video of session now available) Excellent online webinar hosted by De Ruiter/Bayer Australia

Merry Christmas and Happy New Year 2024