Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

When we think of growing tomatoes, we typically picture rows and rows of tall tomato plants climbing high into a greenhouse.

These plant types are known as ‘indeterminate’ tomatoes, and they’re great for extending the growing season and producing high yields. In recent years, Philips has conducted trials on various types and varieties of these indeterminate tomato plants in our own Philips GrowWise Research center in Eindhoven. Results have helped us to develop strategies and practices to maximize crop productivity and quality. However, indeterminate tomato varieties come with their own set of challenges. Because they are so tall, they share the common requirement for a single-layer high-wire growing system with wide paths between rows to facilitate continuous labor for crop maintenance and harvesting. In urban areas, where space and labor are a premium, this can become a problem.

What if there was a better way to grow tomatoes?

To make indoor tomato farming more profitable, we had to overcome two major obstacles: (1) finding ways to make the most of the limited space, while (2) reducing labor costs. And we were not the only ones to acknowledge and address these challenges. Certhon has partnered with HW Seeds and developed a new system, called Gronos. They use varieties of bush tomatoes, which don’t need as much maintenance and produce ripe fruit all at once. Walkways can be removed to make room for plants, as workers don’t have to move around for crop maintenance and harvesting. They have found this works well for outdoor production of tomatoes, but how does it work for indoor farming?

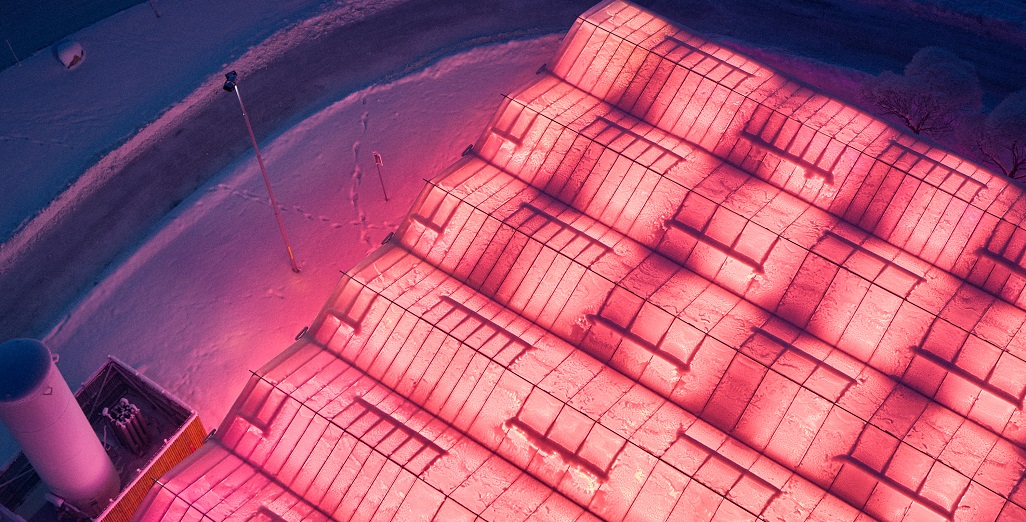

We decided to try growing these smaller varieties of bush tomatoes in high-density, multi-layer indoor systems, and harvesting them all at once at the end of their cycle. We conducted several trials to test this strategy and see if it could produce as much fruit as traditional high-wire systems, with less labor. The results are promising. Not only did we simplify the growing cycle and reduce labor costs, but we also found that we could harvest nearly 1.5 to 2 times more tomatoes per square meter per year compared to traditional greenhouse farming. This means we can produce more tomatoes with less effort and fewer resources, making it a promising strategy for more sustainable and profitable indoor farming.

The market demands cherry tomatoes that are both high in quality and delicious, but achieving these qualities with dwarf tomatoes has proven difficult. To improve overall quality, our current research focuses on managing key parameters such as fruit structure, taste, and shelf-life. Additionally, we aim to improve the ripening homogeneity of cherry tomatoes so that all fruits ripen at the same rate, making automation simpler with a single mechanic harvest. Unfortunately, many dwarf tomato varieties currently available were originally developed for the decorative market and not for high quality or yield. However, the good news is that more companies in the industry are now investing in this new way of growing tasty cherry tomatoes. With continued research and development, we hope to meet the demand for high-quality and delicious cherry tomatoes in the marketplace.

In conclusion, the approach to growing dwarf tomatoes in high-density, multi-layer systems has shown to be a promising solution for vertical farming that maximizes productivity while reducing labor costs. The focus on improving the fruit quality and ripening homogeneity of cherry tomatoes is essential to meet consumer demand. It is exciting to see how this new technique will evolve to help accomplish this goal.

Jarno Mooren is a Plant Specialist at Signify. He is located at the GrowWise Research Center in Eindhoven. His work focuses on setting up and carrying out trials aimed at developing growth recipes that growers can use to efficiently grow crops with desired specifications. He carries out research on light, cropping systems, climate and nutrients for a wide range of crops for indoor farming. In this article, Jarno shares the latest results from tomato trials carried out at the GrowWise Research Center.

For further information, please contact:

Philips horticulture LED solutions by Signify

Daniela Damoiseaux – global marcom manager

Tel: +316 40578311

E-mail:Daniela.damoiseaux@signify.com

About Signify

Signify (Euronext: LIGHT) is the world leader in lighting for professionals and consumers and lighting for the Internet of Things. Our Philips products, Interact connected lighting systems and data-enabled services, deliver business value and transform life in homes, buildings and public spaces. In 2021, we had sales of EUR 6.9 billion, approximately 37,000 employees and a presence in over 70 countries. We unlock the extraordinary potential of light for brighter lives and a better world. We achieved carbon neutrality in 2020, have been in the Dow Jones Sustainability World Index since our IPO for six consecutive years and were named Industry Leader in 2017, 2018 and 2019. News from Signify is located at the Newsroom, Twitter, LinkedIn and Instagram. Information for investors can be found on the Investor Relations page.

New Zealand Contact:

Graeme Neale

Business Development Manager

Specification, Systems and LED Agriculture Solutions

Mobile + 64 21 2254526

Email graeme.neale@signify.com

Level 3, 123 Carlton Gore Road,

Newmarket, Auckland 1023

Australian Contact:

Aart Slobbe

Account Manager Horticulture LED Solutions

+ 61 448 881 338

Email aart.slobbe@signify.com

Suite 022, 44 Lakeview Drive

Scoresby, VIC 3179, Australia

About Signify

Signify (Euronext: LIGHT) is the world leader in lighting for professionals and consumers and lighting for the Internet of Things. Our Philips products, Interact connected lighting systems and data-enabled services, deliver business value and transform life in homes, buildings and public spaces. With 2020 sales of EUR 6.5 billion, we have approximately 38,000 employees and are present in over 70 countries. We unlock the extraordinary potential of light with smart lighting solutions that improve quality of life, and by working towards a sustainable future. We became a carbon-neutral company in 2020, since our stock market listing, we have been in the Dow Jones Sustainability World Index for four years in a row and were named Industry Leader in 2017, 2018 and 2019. News from Signify is located at the Newsroom, Twitter, LinkedIn and Instagram. Information for investors can be found on the Investor Relations page.

For all media releases please send to marie@grower2grower.co.nz or upload directly: https://www.grower2grower.co.nz/article-form/

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

Dynamically controllable LED grow lights for plant nursery

Den Berk Délice improved production predictability and energy efficiency with Philips horticulture intelligent lighting

Intelligent Philips LED lighting at J&A Chrysanten optimizes production and energy efficiency

A holistic approach in a full LED tomato trial resulted in a 50% reduction in heat input

Increasing year-round Capsicum yields through advanced LED lighting