Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Oct 2021

To measure is to know

CARA MET gives growers insight into the root zone

Growers today can use cameras and sensors to take all kinds of measurements in the greenhouse – but the root zone often remains unknown territory. SenseNL is now casting light on this, however, with technology that gives growers insight into exactly what’s happening in the soil or substrate.

It all started fifteen years ago, when Winelis Kavelaars set up the company SOWNet, specialising in wireless sensor networks, now known as the IoT (Internet of Things). In fact, Winelis further developed the technology of Professor Max Hilhorst, who was the first to produce sensors for measuring water content, EC and temperature – and SenseNL was established. Bonny Heeren, who himself has extensive experience in horticulture worldwide, saw the potential of the sensors and stepped in to take care of the marketing.

CARA MET

The name of the sensor that gives growers this insight into the root zone is CARA MET. If this sounds familiar, it could be because this sensor was used by the winning team in the Autonomous Greenhouse Challenge (together with LetsGrow and Hoogendoorn), to further develop the LetsGrow algorithm for optimising irrigation.

Ideal for many situations

The SenseNL platform is not tied to any specific climate computer or substrate. ‘So we don’t exclude anyone,’ says Bonny. The sensor has currently been calibrated for stone wool and can be used in substrate slabs produced by all manufacturers. ‘But calibration for coco is taking place as we speak, and this will be finished by the end of October. We’re also working on a sensor for plants in containers, the “pot sensor” as it’s called. And after that we’ll be introducing the open-soil sensor.’

The sensors can be linked to a climate computer. ‘But we also have our own platform where you can read out the data,’ continues Bonny. ‘We use Amazon’s AWS Cloud environment, so the platform can be professionally upscaled, even with large numbers of sensors. We also use the Ericsson IoT accelerator platform to monitor the sensors and data communication.’

More reliable measurements

SenseNL’s technology is popular not only in horticulture but also in the geotechnical research sector. This is because it can measure the higher EC values, which is also one of the big advantages for horticulture. ‘The present generation of sensors can measure reliably up to an EC of 3,’ says Bonny. ‘This may have been enough in the 1990s, but with current varieties, especially in tomatoes, the EC values can sometimes be as high as 12.’

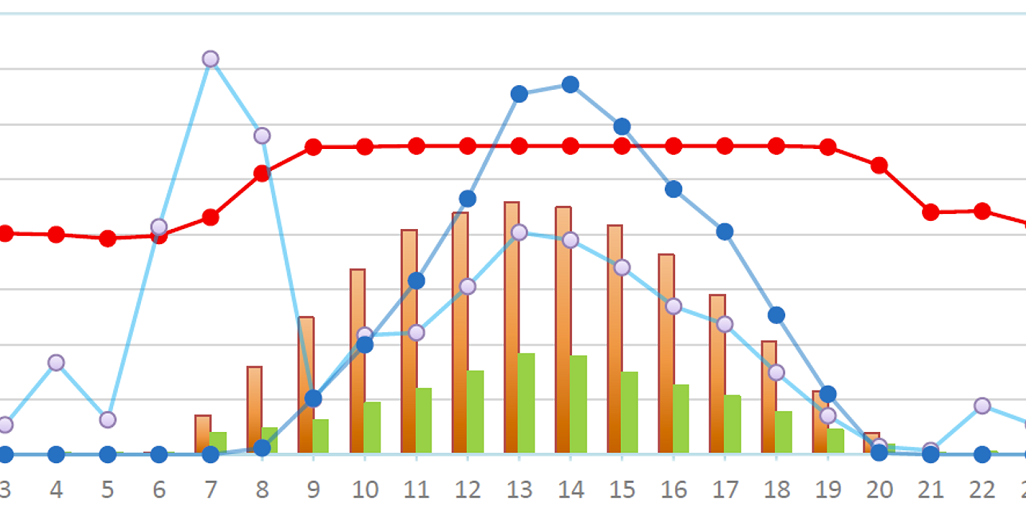

Winelis explains how SenseNL achieves this. ‘A sensor measures both permittivity and conductivity in order to determine the moisture content, EC and temperature. These two parameters are linked, which makes it difficult to measure moisture content at higher EC values. The present technology uses both of them together, but the R&D team at SenseNL has found a way to separate this dependency on each other, allowing you to obtain more reliable measurements in the higher ECs. On top of that they’ve also developed an algorithm to refine this even more. That’s why we have such a unique sensor.’

.jpg)

To measure is to know

Although it may be a cliché, like most clichés it’s actually true: to measure is to know. SenseNL offers technology that enables growers to both take measurements and reliably read out the information. ‘In addition to sending the data over longer distances, we can also provide two-way traffic,’ explains Bonny. ‘So you can not only receive information from the sensor but also update the sensor remotely, if necessary. Growers require information from the root zone, and to obtain reliable information you need to have multiple measuring points, because nothing in the greenhouse is 100% uniform: drippers, substrate, plants and so on. When you have a clearer picture of where your weaknesses are, you can make better use of “precision growing” than if you only have one measuring point. To achieve this, SenseNL applies the motto: not 1 sensor per 10 hectares, but 10 sensors per 1 hectare.’

These new, more reliable insights into the root environment obtained using the wireless CARA MET sensor ultimately make it possible for growers to truly automate their irrigation, potentially as part of the ‘autonomous growing’ principle.

To learn more about Caramet contact:

Kevin Oei

Product owner CARA MET sensor

Web – https://caramet.com/en/

E-mail – info@senseNL.com

Ph +31 (0)85 876 89 09

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Greenhouse Production in the Future – Mike Nichols

(Video of session now available) Excellent online webinar hosted by De Ruiter/Bayer Australia

An observation about Chlorosis effecting Tomato Plants.

Design a Semi Closed Greenhouse with Hortinergy

Direct Air Capture (DAC) is now a reality— Onsite CO2 generation scalable for both large and small operations