Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Jul 2021

Interesting Idea Grabs My Attention (Technical)

Just one heating and vent setting

Last month I posted the article news/post/humidity-influences–technical-/ This article is a follow up to that post. I have engaged with several SME as I am interested if there are other ideas of dealing with humidity.

Last week, in a zoom meeting, another advisor pointed out an option I had never really considered before which was applying just one heating and one venting setpoint. I am not sure that many current environmental computer systems are able to achieve this, but I know there are systems that can. This article is about creating some debate around this topic.

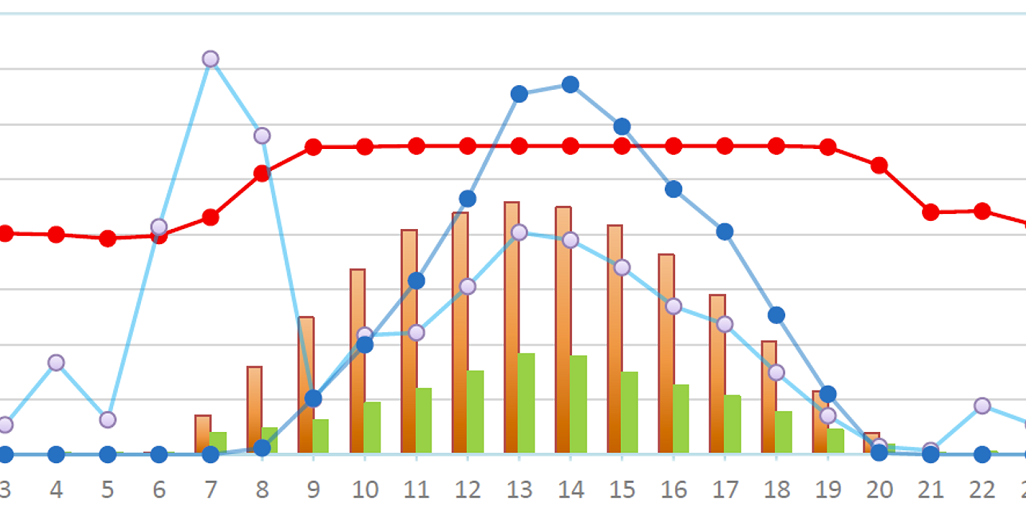

The concept is to set the desired night-time temp as the single heating temperature. As an example, 16 degrees for the entire 24-hour period. Then you come up with a vent temperature which could be as high as 25 degrees. The next thing to set minimum vent setpoints and in this example we will use 10%. Next is where the influence comes into action.

Adding a temperature influence:

For example, if the temperature does drop to 15 degrees the minimum vents are overridden and the vents will go to zero. Conversely for every degree over your setpoint the vents will react by opening progressively until they reach your maximum vent opening at the set vent temperature.

There is still the option of using other influences on wind direction/speed and rain, Co2 and absolute humidity (AH) etc. There is also the desired vent proportionate (P) bands to consider. Depending on the outside temperature and time of the year by slowing or speeding the vents opening and closing ability will help maintain a steady climate. This setting will also control cold air from ‘falling’ onto the heads of the plants causing issues such as botrytis.

Humidity:

Humidity is a key factor; you must be prepared to use enough minimum pipe temperature to keep an active climate. In terms of AH, you could still use this influence, especially if you have screens, if you felt the humidity control was not sufficient. If you had a temperature box above the screens you could also use this to control the AH, but in theory, and if it is cooler outside, then inside the minimum vent will have some natural control over the AH in the crop, especially if there is venting above the screen?

Minimum Pipe:

The minimum pipe could be tied to the radiation/sum, basically the pipe temperature decreases to your desired set point as the sun takes over the climate. Vice versa if the weather is poor and the temp is not at your desired setpoint then the pipe remains.

CO2:

This setting is key for me as in the morning period I would want a high level of CO2 but not at the expense of very high humidity. If the minimum vent was causing too much spewage of CO2 out of the vents, and with the proviso the crop is strong and free of disease, I would consider the maximum vent setting in this period. I would encourage all growers to observe this key point as it may influence the minimum vent setpoints during this part of the day.

This one setting, with the right influences, has potential to be a quite simple yet effective way to control the temperature and humidity in your environment and create air exchange. You may find you have to tinker with the temperature/venting setpoint if the 24hour temperature is either too high or low in regard to growth rates/loading etc.

Perfectly controlling a greenhouse environment is difficult and when you have a super environmental computer with all the bells and whistles it could be easy to use every function available but is it always necessary?

Article written and compiled by Stefan Vogrincic

All Article’s checked and edited by Marie Vogrincic

I appreciate your comments. Please feel free to comment on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Greenhouse Production in the Future – Mike Nichols

(Video of session now available) Excellent online webinar hosted by De Ruiter/Bayer Australia

An observation about Chlorosis effecting Tomato Plants.

Design a Semi Closed Greenhouse with Hortinergy

Direct Air Capture (DAC) is now a reality— Onsite CO2 generation scalable for both large and small operations