Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Nov 2020

Uneven delivery of irrigation water

Keep it clean

Crops will grow in a large range of water content (WC) and electrical conductivity (EC), but it is better to achieve perfect delivery and output for every slab or bag to maximise plant health and production. If I was able to trust my irrigation system 100% to deliver the exact same volume to each plant every time, then the substrate required per plant could be reduced. The extra volume of substrate is predominantly a necessary water buffer to mitigate uneven watering systems.

Pressure compensating drippers (PCD) have always been my preferred delivery method and they work extremely well. Nutrient Film Technique (NFT) and Deep Flow Technique (DFT) systems have no substrate costs but have risks associated with potential breakdowns. However, they are popular with some smaller to medium sized growers. Most NZ greenhouse growers grow in substrates and use PCD to supply refreshment/irrigation. The way I delivered irrigation has barely changed since I started growing 25 years ago. The aspects that have changed are the compositions of the substrate and ever improving technology assisting WC and EC controls. The choice of substrate is important and no one substrate provider has convinced every grower their product is the best, in other words there is good competition and very good substrates available in the market that suit the needs of many.

EC in Substrates:

An ongoing basic requirement for substrates is controlling bound EC around the rootzone. It requires runoff to control EC from becoming too high. Increasingly uneven irrigation delivery per plant will require more irrigation to reduce high EC bound in rootzone where not enough flushing has occurred. The opposite effect is extra irrigation will drop the EC too low in bags not affected by uneven delivery within the same irrigation zone. It is a loose-loose scenario.

Delivery:

As mentioned above the delivery of irrigation via PCD is the most popular way to irrigate and has not altered much in 20 plus years. You may be aware of the lids/caps you place on top of the propagation cube; this is to increase the surface area the irrigation water is applied. The concept is to create a better root cone and reduce evapotranspiration out of the block. It certainly sounds and looks impressive but these caps may be expensive and be time consuming to both place on the plant block and remove and clean each season. However, at least they provide another option to the irrigation spikes. Delivery systems is an area I believe could be explored further. However, reinventing the wheel is not what I am suggesting but irrigation systems are an area that still have room for improvement.

Standard Deviation:

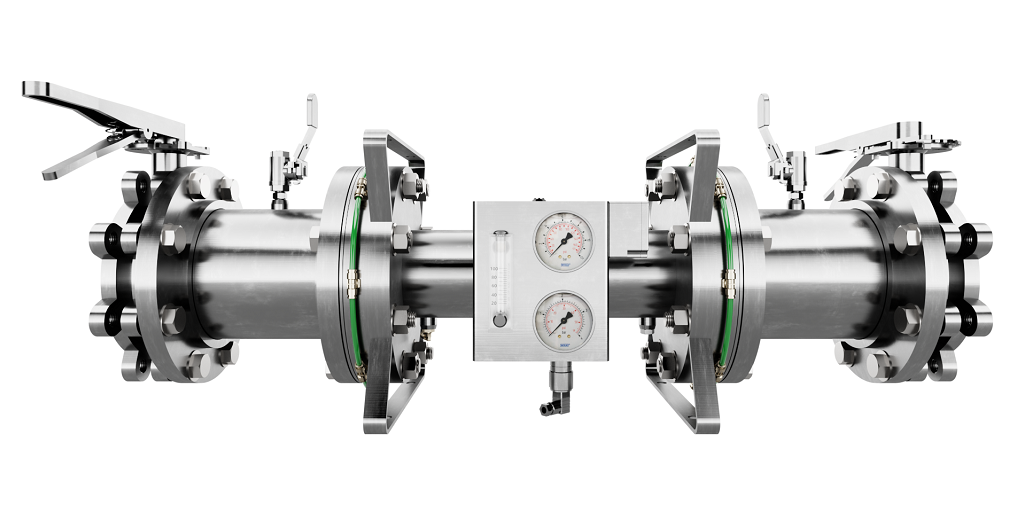

If I notice a crop where plants appear uneven and I think it may be the irrigation I would suggest a quick test to measure the difference between several PCD. If there is a large range between PCDs check the water pressure to make sure the PCD are actually getting the correct pressure to open the manifolds. If that is good then remove and open a few PCD’s to check for gunk.

If the irrigation system is not as accurate as they should be consider upgrading and even replacing parts of the system, especially the PCD and the irrigation pipes. If you wish to attempt to clean and flush the lines do this with caution as you may loosen thick gunk which can cause additional short- or long-term issues. What I suggest is if you do upgrade your system keep it clean from the beginning with products such as Huwasan. A clean irrigation system is crucial for growing crops evenly and effectively.

Sanitising new PCD irrigation systems from the start will improve long term accurate per plant delivery.

I appreciate your comments. Please feel free to comment on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

Article Written and compiled by Stefan Vogrincic, Consultant, Grower2Grower

Article Edited by Marie Vogrincic, Editor, Grower2Grower

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Less fertilisation and higher yields with Ambiorix iron polyphosphate

Bluelab Introduces OnePen™

Free Webinar on Controlling Waterborne Pathogens in Greenhouses

Whitepaper elaborates on safe recirculation of irrigation water

Introducing Moleaer’s Trinity: Revolutionizing Agriculture with Advanced Nanobubble Technology